Business

- Global Business

- Test

- Water Convergence R&D

- Water Campus

- Test Beds

Perform new technology performance evaluation to enhance technology completion and enter the global water market

Comprehensive to perform technology improvement of water related technologies (parts, equipment, process technology, materials, unit element technology, control system) developed by companies and universities, and to perform performance evaluation of new technologies necessary to enter the domestic and overseas water market test-bed facilityFacility Overview

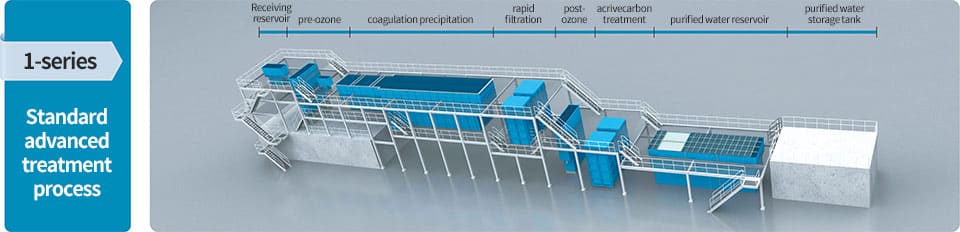

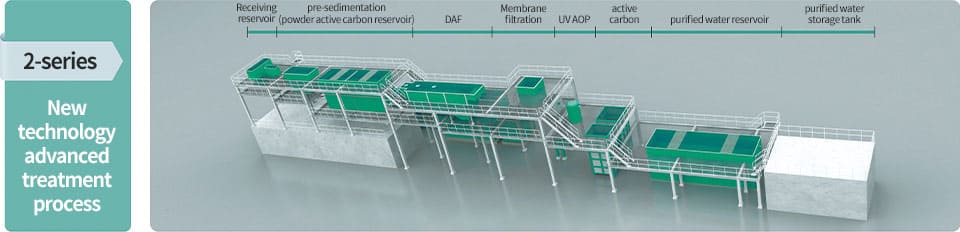

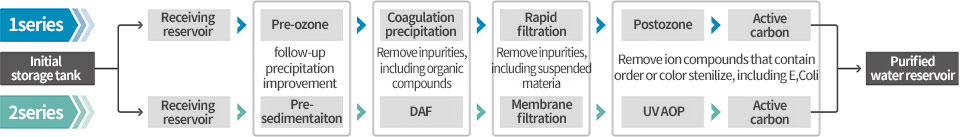

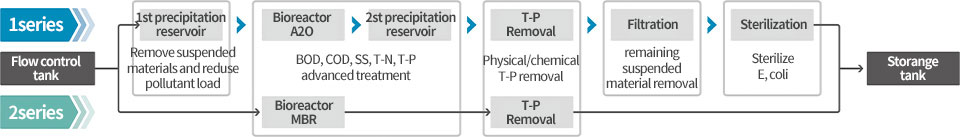

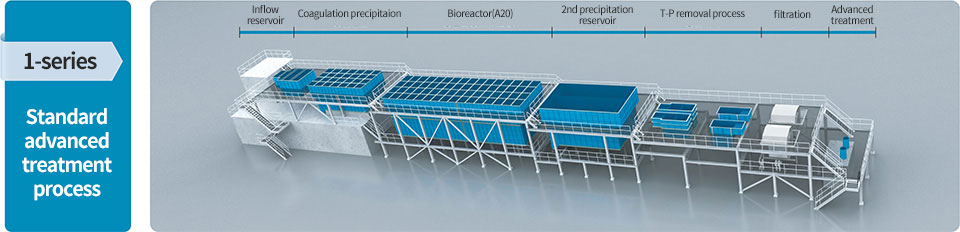

1-series

| Type | Volume | Process Details |

|---|---|---|

| Type1-Series (Standard Process) |

Volume1,000㎥/day | Process DetailsPre-ozone + Chemical coagulation sedimentation + Granular rapid filter + Post-ozone + activated carbon filter + Disinfection (chlorine) |

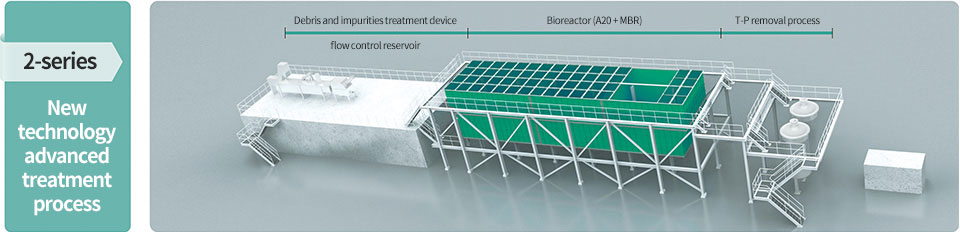

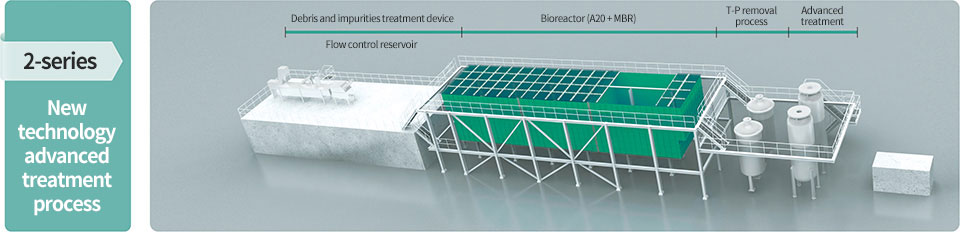

2-series

| Type | Volume | Process Details |

|---|---|---|

| Type2-Series (New Technology) |

Volume1,000㎥/day | Process DetailsPowder Activated Carbon (Pre-sedimentation) + Dissolved Air Flotation (DAF) + Membrane Filtration + UV AOP + Activated Carbon Filter + Disinfection (chlorine) |

Plant Cross Operation for Verification Test

Contact

Facility Overview

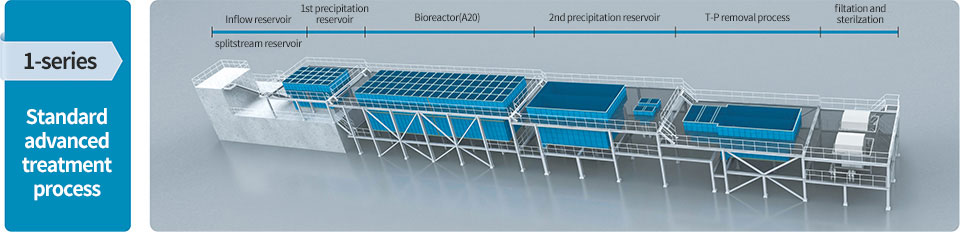

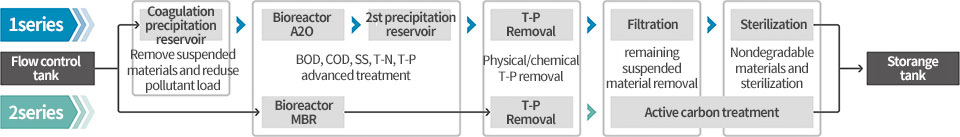

1-series

| Type | Volume | Process Details |

|---|---|---|

| Type1-Series (Standard Process) |

Volume500㎥/day | Process DetailsComprehensive contaminant processor (Common) + 1st precipitation reservoir + A2 / O + 2nd precipitation reservoir + T-P Removal (drug flocculation sedimentation) + fiber filter + disinfection (UV) |

2-series

| Type | Volume | Process Details |

|---|---|---|

| Type2-Series (New Technology) |

Volume500㎥/day | Process DetailsComprehensive contaminant processor (joint) + Bioreactor + MBR (Membrane Bio Reactor) + T-P Removal Facility (Up-flow Sand Filter) |

Plant Cross Operation for Verification Test

Facility Overview

1-series

| Type | Volume | Process Details |

|---|---|---|

| Type1-Series (Standard Process) |

Volume500㎥/day | Process DetailsComprehensive contaminant processor (common) + primary treatment (drug sedimentation) + A2 / O + 2nd precipitation reservoir+ T-P removal (DAF) + fibrous filter + ozone oxidation |

2-series

| Type | Volume | Process Details |

|---|---|---|

| Type2-Series (New Technology) |

Volume500㎥/day | Process DetailsComprehensive contaminant processor (common) + Bioreactor + MBR (Immersed Membrane) + T-P Removal (Media Filtration Facility) + Activated Carbon Filter |

Plant Cross Operation for Verification Test

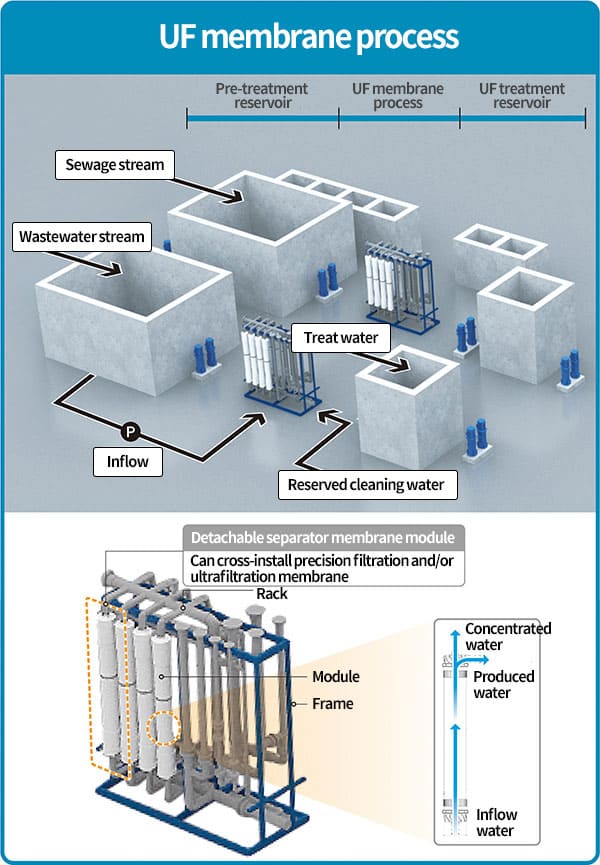

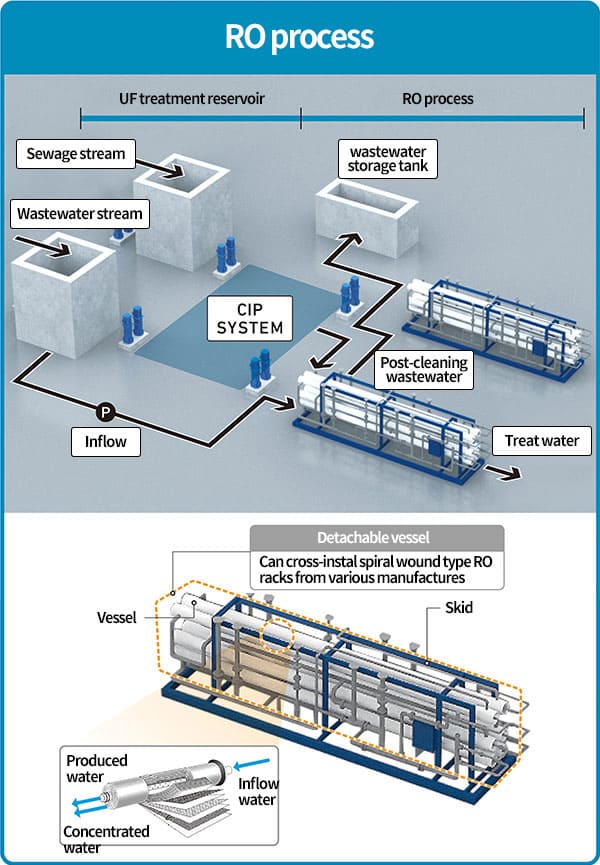

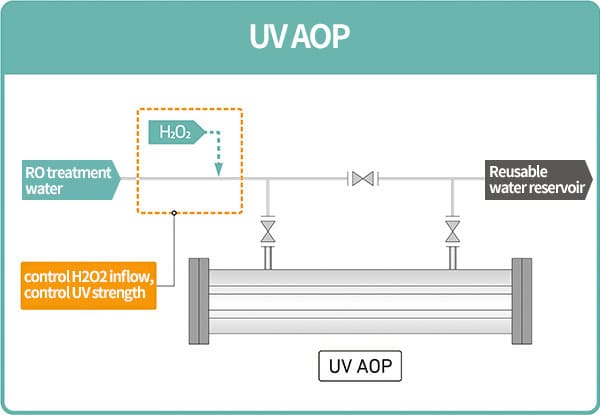

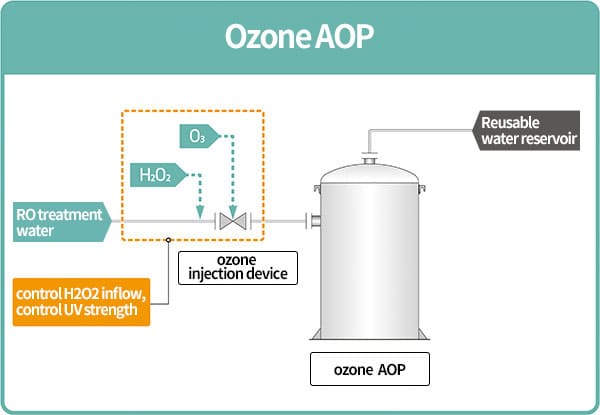

Facility Overview

| Type | Volume | Process Details |

|---|---|---|

| Type1-Series(Sewage) | Volume500㎥/day | Process DetailsPre-treatment (Multimedia Filter) + Membrane filtration (UF) + Membrane filtration(RO)+ ozone oxidation |

| Type2-Series(Wastewater) | Volume500㎥/day | Process DetailsRapid Filter + Activated Carbon Filter + Membrane Filtration (UF) + Membrane Filtration (RO) + Disinfection (UV) |

Facility Details

| Facility | Technology | Target | |

|---|---|---|---|

| Common | Method of Construction |

|

|

| Management (Control System) |

|

||

| Measurement |

|

||

| General Material |

|

||

| Water treatment equipment | Flocculation / sedimentation |

|

|

| Separation Membrane |

|

||

| Filter |

|

||

| Disinfection |

|

||

| medicine |

|

||

| Sludge Treatment |

|

||

| Sewage·Wastewater | Method of Construction |

|

|

| Management (Control System) |

|

||

| Water treatment equipment | Pre-treatment |

|

|

| Air Diffuser |

|

||

| Reclaimed Purification | Method of Construction |

|

|

In addition to the specified technologies, it is possible to test various technologies using Test-Beds. For more information, contact Korea Water Cluster Test-Beds Support Department (053-601-6052).

It is a space where companies and universities can freely install equipment and processes on a small scale to conduct technology development and experiments on R & D, and provide necessary utilities such as raw water (process water), site, electricity, and the Internet

Facility Overview

| Type | Unit | Raw Water and Process Water Supply |

|---|---|---|

| Purification | Unit15 |

Raw Water and Process Water Supply

|

| Sewage | Unit10 |

원수 및 공정수 공급량

|

| Wastewater | Unit10 |

원수 및 공정수 공급량

|

| Reclaimed Water | Unit10 |

원수 및 공정수 공급량

|

| Type | Room | Area(㎡) | Type | Room | Area(㎡) |

|---|---|---|---|---|---|

| Purification | P101 | 197.02 | Sewage | S101 | 192.52 |

| P102 | 195.59 | S102 | 190.77 | ||

| P103 | 131.41 | S103 | 132.42 | ||

| P104 | 130.80 | S104 | 131.67 | ||

| P105 | 130.18 | S105 | 130.92 | ||

| P106 | 131.42 | S106 | 132.42 | ||

| P107 | 130.80 | S107 | 131.67 | ||

| P108 | 142.04 | S108 | 130.92 | ||

| P109 | 130.80 | S109 | 132.42 | ||

| P110 | 131.42 | S110 | 144.64 | ||

| P111 | 130.18 | Wastewater | W101 | 192.52 | |

| P112 | 130.80 | W102 | 190.77 | ||

| P113 | 131.41 | W103 | 132.42 | ||

| P114 | 195.59 | W104 | 131.67 | ||

| P115 | 197.02 | W105 | 130.92 | ||

| Reclaimed Water | R101 | 163.29 | W106 | 132.42 | |

| R102 | 195.84 | W107 | 131.67 | ||

| R103 | 135.52 | W108 | 130.92 | ||

| R104 | 155.86 | W109 | 132.42 | ||

| R105 | 146.01 | W110 | 144.64 | ||

| R106 | 144.87 | - | - | - | |

| R107 | 145.44 | ||||

| R108 | 146.01 | ||||

| R109 | 181.23 | ||||

| R110 | 182.56 |

A separate outdoor space for pilot experiments that is unacceptable in the User-customized area, providing process water and electricity

Facility Overview

-

Location

- - right, right, center of empty spot of Test-Beds

-

Area

- - Purification 2,250㎡, Sewage/Wastewater 2,200㎡, Reclaimed Water 2,400㎡

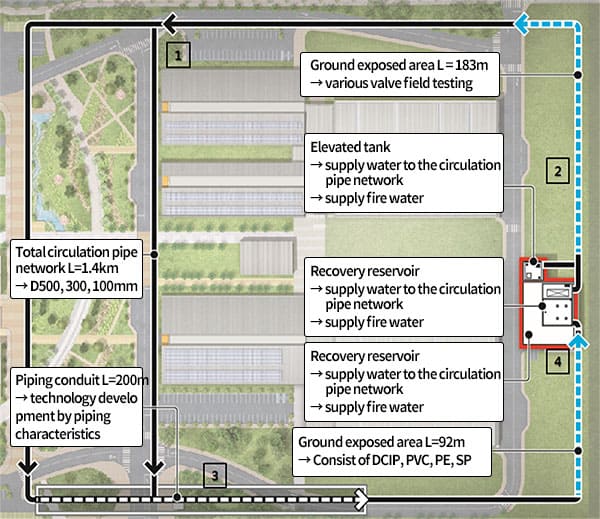

Facility Overview

-

Configuration

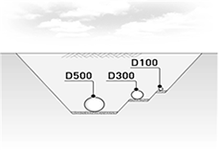

- - Circulation Pipe Network 1.4km(laying920m, Piping Conduit 200m, Exposure 280m) 3 Column(D500, 300, 100mm), and Indoor water supply equipment (Indoor water supply pipe, Water meter, etc)

- - Piping Conduit : Length 200m, Width 3.5m, Height 2.9m

-

Accessory Facilities

- - Recovery Reservoir(800㎥), Elevated Tank(Capacity 400㎥, Height 26.8m), Valve, flow meter, pressure gauge, air valve, etc

-

-

① Total Circulation Pipe Network ② Outdoor Pipeline ③ Pipe Conduit ④ Indoor Water Supply Test

Pipe Corrosion, Pipe Materials (painting materials, etc.) Deterioration, etc. Long-Term physical property test Performance test of accessory facilities such as leak detection equipment and measuring equipment Performance test such as pipe joints, repair reinforcement method, etc Performance test of indoor water supply facilities such as indoor piping and tap water -

Accessory Facilities

- - Recovery Reservoir(800㎥), Elevated Tank(Capacity 400㎥, Height 26.8m), Valve, flow meter, pressure gauge, air valve, etc

-

- Pipe Network Test Technology

Type Verification facility linkage plan Pipe Materials - Performance evaluation of existing pipe materials

- Performance evaluation by pipe material in the pipe network testing area

- Material, mechanical and chemical properties during material testing area

- Hygiene safety standard test (introduced test analysis equipment in 2019)

- Long-term (or extreme conditions) property test of existing materialsMeasurement facility Water quality measurement Type approval and accuracy test for turbidity and residual chlorine continuous automatic measuring device for drinking water Reinforcement materials and methods - Apply various repair reinforcement methods and perform performance evaluation using ground exposure pipe section

- Performance test for pipe rehabilitation and repair

- Analysis of physical and chemical properties of reinforcing materials inside and outside the pipeAccessory facility Leak Exploration Facility Performance Evaluation of Leaking Facility according to Artificial Leakage Generation Conditions and Various Environmental Conditions Corrosion Prevention Facility Evaluation of Corrosion Control Effect of Corrosion Prevention Technology using Outer Circulation Buried Pipe and Underground Cavity Pipe Pipe Washing Facility Evaluation of the efficiency of debris removal devices, materials, and methods inside of the outer circulation buried pipe Water shock

prevention facilityEvaluation of water shock prevention equipment efficiency using pump and valve verification pipeline in rapeseed performance evaluation test equipment Pipe Network Diagnosis Facility Performance evaluation of imaging equipment, physical and electrical signal-based diagnostic equipment (ultrasonic waves, electromagnetic fields, etc.) for evaluating sound life of pipelines and attached facilities for buried pipes or outdoor exposure pipes Pipe network operation management system Real-time measurement, control, communication equipment and system performance evaluation in pipe network system

Pipe network operation tools such as pipe network analysis, leak analysis, accident and fault response, pump scheduling, pressure reduction and valve controlIn addition to the specified technologies, it is possible to test various technologies using Test-Beds. For more information, contact Korea Water Cluster Test-Beds Support Department (053-601-6052).